Used for data-logger-based data acquisition. (Corrected for crosswind effects.)Ģ.5 to 357.5° in CSAT3B coordinate system (0 to 360° customized)Ħ3.1 x 12.3 x 43.3 cm (24.8 x 4.9 x 17.0 in.)Ĭurrent Required for 10 Hz Measurement RateĬurrent Required for 100 Hz Measurement RateĪccuracy specifications assume the following:

To the anemometer axes T s is sonic temperature in degrees Celsius.)ĭetermined from three acoustic paths. U x, u y, u z, T s (u x, u y, u z are wind components referenced 40 to +50☌ (equivalent to 305 to 368 m s -1 in speed of sound) The controller controls the heaters by increasing or decreasing the voltage to get the appropriate wattage to keep ice from forming on the sensor.

#Sonic anemometer full

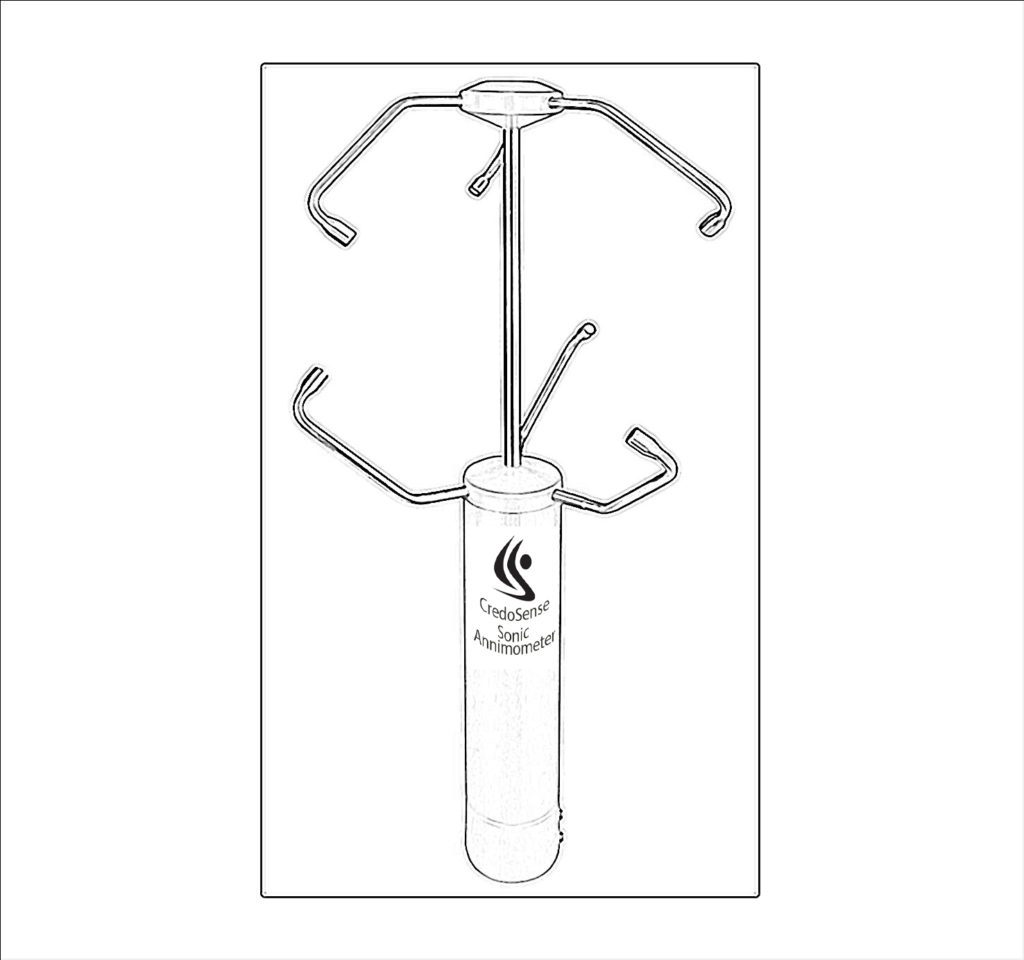

The heaters are controlled on two zones and require 150 W at full power. The enclosure uses connectors for incoming power, heaters, temperature sensors, temperature/RH, RS-485(2), and USB. These moving parts expose the sensor to failure. The CSAT3H heater controller is a polycarbonate enclosure sized 20.32 x 25.4 x 15.24 cm (8 x 10 x 6 in.). Conventional wind vane anemometers have mechanical rotating parts. There is an ambient temperature and relative humidity sensor that is standard for use with the controller, or the data can be provided through a user-supplied temperature/RH sensor. The controller requires a temperature/RH input.

The CSAT3BH has a separate controller that is used to control the heating algorithm of the sensor. The smart heating uses environmental conditions and a controller to apply variable heating to the sonic anemometer to keep the body and transducers free of ice and snow. The CSAT3BH is designed to prevent ice from forming on the arms and fingers of the system. Zone 2 provides heating to all the transducers.The CSAT3BH provides integrated two-zone smart heating:

0 kommentar(er)

0 kommentar(er)